Its easy processing allows it to be used in a wide range of application, both as a homopolymer or copolymer. Polypropylene has low specific gravity, good temperature and solvent resistance, good dielectric properties, high chemical resistance and tensile strength but low mechanical resistance compared to engineering plastics, and poor light resistance. PP is the most widely used thermoplastic material in the automotive industry. It is widely used in many commonly used objects.

Fillers

Depending on the client’s requirements, we at Crea use it pure or with the following fillers:

- glass fibre: which leads to high rigidity combined with excellent thermal and resilience properties

- carbon fibre: among the most widely used reinforcements for creating

compounds for applications requiring high mechanical performance. Compound elastic modulus and breaking load increase with the increase in the percentage of carbon fibre. - talc: polymers filled with talc show an increase in elastic modulus and creep resistance compared to those filled with calcium carbonate. Talc-filled PP is used mainly in the automotive and household appliance industries. The talc percentage must be correct so as not to compromise stability at high temperature, as degradation resistance is generally low

Benefits of polypropylene:

- good resistance to chemicals and solvents;

- good electric properties;

- easy to process;

- low specific gravity;

- cost saving.

Applications

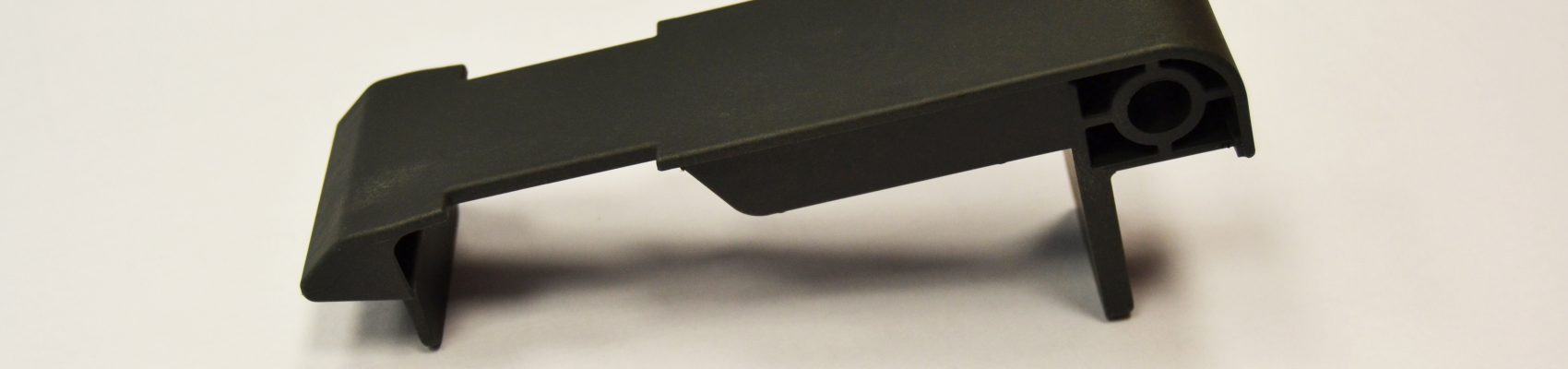

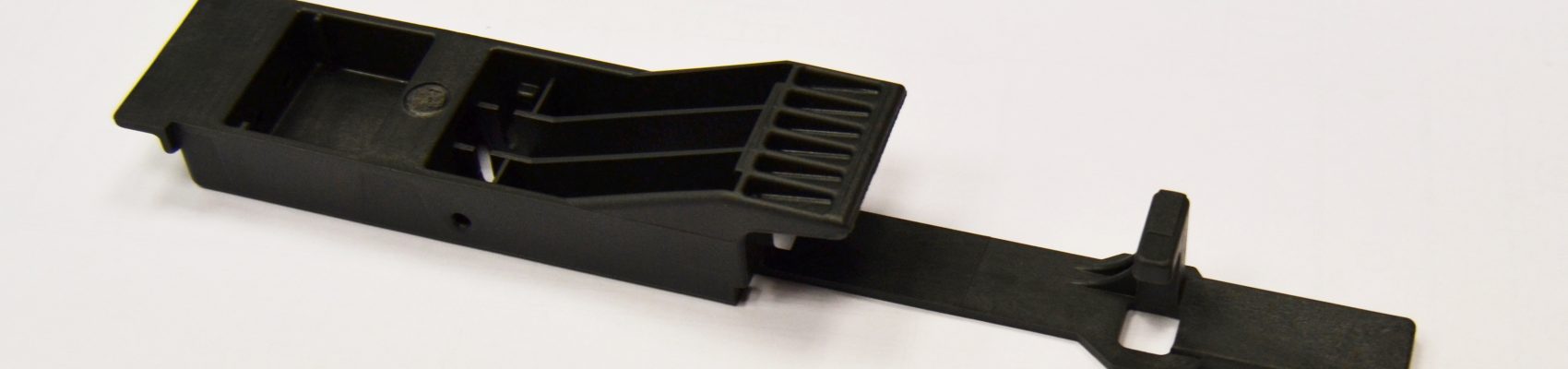

Automotive industry

Widely used in the automotive industry thanks to its good electric resistance.

Everyday objects

It is found in various everyday objects.