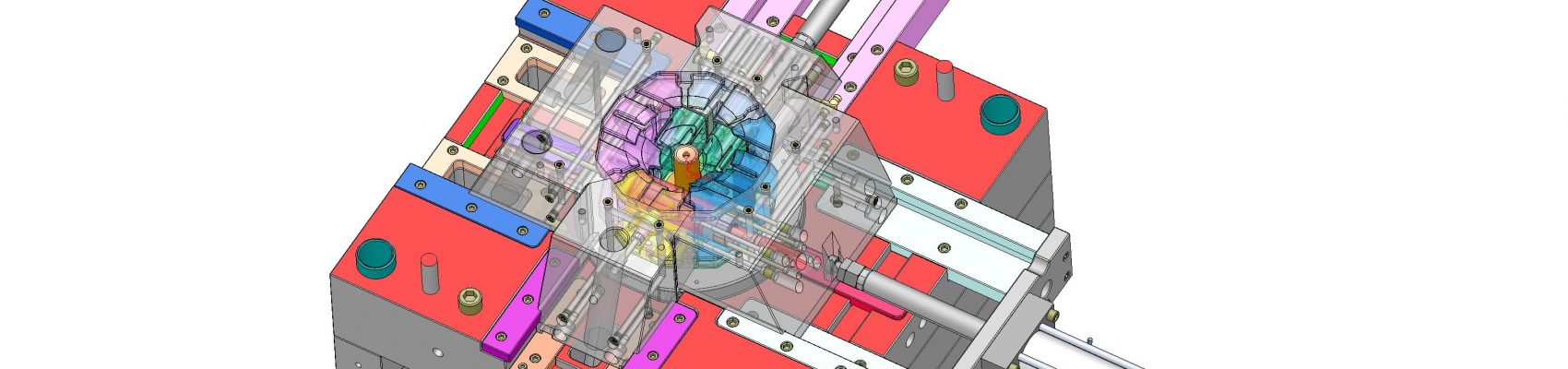

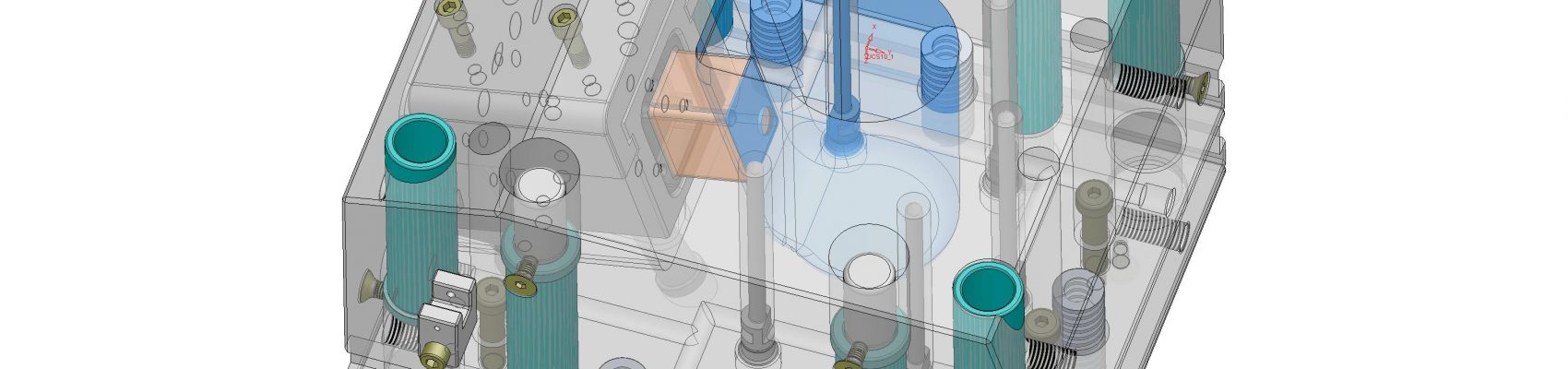

Our technical department designs moulds using modern 2D and 3D CAD systems, which allow our technicians to combine the client’s requirements with the specific features of the injection moulding process. Every mould is designed with utmost accuracy, ensuring functionality, durability, and quality of both the mould and finished product. Designing moulds requires the collaboration of those who will manufacture the mould and then of who will work with it. This is why our technical department doesn’t just deal with numbers but also with upstream and downstream requirements, engineering them the best way possible.

Based on your idea, we provide a co-design service, helping you design both the item and mould. Together we will meet your requirements, providing the technical guidance to help you choose the best solution possible. A careful design that takes all the pros and cons into account allows us to create an excellent mould in close collaboration with our technical department. We don’t like quick fixes. Goals can be reached in different ways but we aim at following the best one possible.

We provide a co-design service, supporting our clients step by step also during the engineering phase of their ideas, assessing any aspect together, even through the development of prototypes. Once the product appearance and materials are defined, the mould design phase begins, supported by the filling simulation software if necessary.

If you need to transform the material of your item from metal to engineering plastics, our team will support you by designing the moulds until obtaining the engineering plastic piece.

Replacing metals with engineering plastics is possible. This transformation occurs upstream during the design phase. We create innovative and cost-saving pieces featuring high thermal, chemical, electrical, and wear resistance, with physical and thermal characteristics similar to those made of metal, but with reduced weight. We achieve this simply by using the right engineering plastic. Once we have identified the right engineering plastic capable of providing the performance required, we reinvent the piece.

Our in-house mould construction workshop and internal moulding process allows the mould design department to have a complete overview of the entire process and know the critical aspects of every stage, collaborating with the various departments.